Microtech Socom Bravo – T/E DLC Titanium/Carbon Fiber Scales – 261-1 DLCTCFTI

$496.95

Availability: In stock

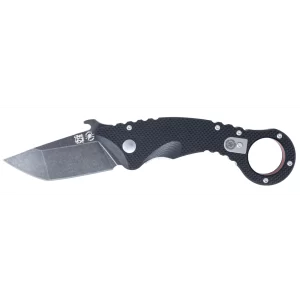

The SOCOM Bravo tactical folding knife, developed by Microtech in collaboration with Rike Knife, is a unique combination of innovation and time-tested tradition. Based on the classic Socom model, this folding knife is an example of modern design and functionality that can meet a wide range of needs.

An important feature of the SOCOM Bravo is its versatility: this knife is ideal for both everyday use in urban conditions (EDC) and for use as a tactical knife in extreme situations in nature. The Tanto blade profile, characterized by its strength and effectiveness in penetrating strikes, is made of high-quality M390 steel. This steel is known for its exceptional wear resistance and ability to maintain sharpness for a long time. DLC treatment not only gives the blade an impressive appearance, but also significantly increases its strength and corrosion resistance. The blade is opened using a pin, and a frame-lock is responsible for fixing it in the open position.

The handle of the SOCOM Bravo knife is made of durable titanium with a DLC coating, which not only makes it aesthetically attractive, but also increases wear resistance. Carbon fiber overlays on the handle not only improve the appearance of the knife, but also contribute to a more confident and comfortable grip, which is critically important in both everyday and tactical use scenarios. Additional convenience is the presence of a pocket clip and a lanyard hole, providing ease and convenience of wearing and quick access to the knife in any situation.

So, the SOCOM Bravo from Microtech is not just a folding knife, it is a multifunctional tool that will be indispensable both in the urban environment and in the conditions of survival in the wild. Its high-quality materials, thoughtful design and versatility make it an ideal choice for those who are looking for reliability, style and functionality in one tool.

The blade is made of M390 steel. This is a premium martensitic powder steel with a high content of chromium and vanadium. It is produced by the world-famous Austrian concern Bohler — Uddeholm AG. This steel is recognized as one of the best in the world for its wear resistance, high anti-corrosion properties, excellent strength and impact toughness. Currently, it is a very popular material and is successfully used in the production of premium serial knives, as well as custom and author’s models. Blades made of this steel are hardened to 58-62 HRC. It has excellent cutting edge durability. However, it is worth noting that the downside of this property is not quite easy sharpening.

The handle is made of titanium with carbon overlays. Titanium is a material with excellent mechanical properties. It is quite strong, rigid and has a small weight compared to other popular metals used in knife handles. The handle made of titanium alloy is heat-resistant, physically inert and not subject to oxidation. Externally, titanium handles look luxurious and perfectly complement the steel of the blade of any brand. Despite the complex degree of processing, high viscosity and high cost, this material is still quite common among knife makers.

The Microtech Socom Bravo features a DLC Black Titanium Frame with Carbon Fiber inlays. Manufactured by Rike Knives for Microtech, this Socom Bravo has an M390 DLC Black finished tanto blade with a standard edge. It also has a DLC Black Titanium pivot collar. This knife features the Microtech Talon logo and the Rike Knife logo on the front of the blade.

SPECIFICATIONS:

- Blade Length: 4.0″

- Closed Length: 3.75

- Overall Length: 9.09″

- Blade Material: M390 Stainless Steel

- Blade Style: Tanto

- Blade Edge: Standard

- Blade Finish: Black DLC

- Handle Material: Black DLC 6Al4V Titanium with Carbon Fiber inlays

- Frame Lock

- Pivot: Bearings

- Pocket Clip: Black DLC Titainum (Tip Up, Right)

- Weight: 4.67oz.

- Designed by Tony Marfione

- Manufactured By Rike Knife for Microtech